Cold Rolled Products

Special orders also available on request. All within 7-10 days nationwide.

C-sections

140mm, 170mm, 200mm, 240mm deep C-Sections available with struts, tie wires and sleeves.

Z-purlins

140mm, 170mm, 200mm, 240mm deep purlins in a range of gauges. Available with all ancillary items including sleeves, anti-sag rods, apex ties, cleats and bolts.

Eaves Beams

170mm, 200mm, 240mm deep complete with struts.

Cleats

The following cleat diagrams and dimensions apply to all our sections and can therefore be used with our entire range of cold rolled products. If you have any queries, or require technical advice, contact us.

Hayes E&C Ltd’s range of C-Sections provide useful structural solutions to an array of construction and industrial applications, e.g. Mezzanine Floor beams, cladding rails, structural support members (gable rafters and columns), window and door trimmers, brickworks restraints and wind bracing.

Features

- Pre-Galvanised – no additional finishing or painting required

- Pre-punched holes -minimising assembly time and errors

- Wide range of sections, gauges and spans to suit an array of applications

Applications

- Side rails – Our C-sections are compatible with the Z-purlin range and can be used as a substitute.

- Mezzanine floors – C-sections can be used either as primary or secondary floor beams in mezzanine floors.

- Parapet posts – used in a ‘back to back’ formation, C-sections provide a cost effective alternative to hot rolled sections in a parapet situation.

- Brick work restraints – as an alternative to hot rolled sections, C-sections used to restrain brick work offer benefits of significant cost savings, light weight on-site handling and no additional finishing.

- Door posts / windows – C-sections can also be utilised for framing doors and windows. Due to the fact that the sections are the same size as Z-purlins, alignment on-site can be achieved with minimal effort.

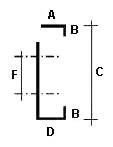

Dimensions

The diagrams below refer to all C-section sizes (C-140, C-170, C-200 and C-240).

Side rail butted system: The butted system offers a simple cleat connection (the cleat is welded or bolted to the hot rolled steel section) where two butted C-sections are fastened directly to the cleat. This is suitable for smaller buildings, short or uneven span or light loading applications.

This system can also cater for single bay situations, therefore can be used in conjunction with other cladding support systems. Spans of up to 8m can be accommodated, depending on the loads involved, where the cladding or the liner tray offers the correct lateral support by the way it has been fixed.

Z-purlins are cold formed structural sections, manufactured from high tensile Z39 steel and are pre-galvanised so no additional finish is required. This product satisfies the requirements of BS5950: Part 5 (1998). Their high strength to weight ratio (as with all our cold rolled sections) enable practical substitution for hot rolled steel sections whilst easing handling on-site and during installation. The ‘Z’

in Z-purlin relates to the shape of the section and the structural strength of this product is mostly attributed to the shape.

Features

- Pre-Galvanised – no additional finishing or painting required

- Pre-punched holes -minimising assembly time and errors

- Wide range of sections, gauges, spans and ancillary items to suit an array of applications

- Roof Purlins – Depending on the application, Z-purlins can be used in a single or double span arrangement. They are ideal for Heavy Bay End sleeved and butted systems. The design of our Z-purlin range ensures flexibility, so can be used with a wide range of hot rolled sections in addition to other cold rolled products and profiled sheeting.

- Side rail / Sheeting rails – Offering comparable performance to our C-sections, Z-purlins can be used as side rails which simplifies the specifying and ordering process.

Dimensions

The diagrams below refer to all Z-section sizes (Z-140, Z-170, Z-200 and Z-240). The dimensions for a specific Z-section can be referenced in the table below.

Z-purlin

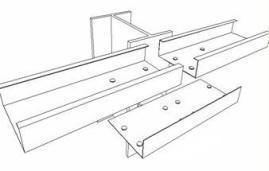

Purlin butted system

Used in the butted system, two Z-purlins are fixed using a cleat (the cleat is welded or bolted to the hot rolled steel section). This system is suitable for single bay or low loading applications with up to 8m spans. It is also compatible with other cladding support systems.

Purlin sleeved system

This system is used primarily for spanning over two or more bays. The sleeved system incorporates a cold rolled sleeve to which two Z-purlins are bolted to the cleat. This system will cater up to 12m spans depending upon the loading of the cladding etc.

Side rail butted system

As with the purlin butted system, Z-purlins used in a side rail application can be fastened directly to a cleat, which itself can be bolted or welded to the hot rolled section. Again, this is suitable for smaller buildings, short or uneven span or light loading applications.

Side rail sleeved system

Like the purlin sleeved system, Z-purlins used in a side rail application cater for spanning multiple bays or supporting heavier loads with the incorporation of a sleeve, fixing the purlins to the cleat. This significantly increases the loading capability of the system.

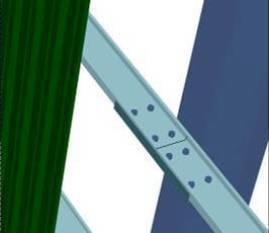

The following fixing systems apply mostly to sleeved purlins used in multi-bay or heavy end bay applications.

Staggered Sleeve Arrangement (Double Span)

Using a staggered sleeve arrangement increases the loading capabilities of the system in comparison to the butted system, whilst still offering a cost effective solution. In the diagram below you can see the staggered arrangement of sleeves. Care must be taken during installation to maintain erection sequence.

Using this system, sleeves at the ends of the span are positioned at every support. Internal bays have sleeves staggered on alternate supports and utilise lower gauge (thinner) sections and sleeves. The effect of staggering reduces the number of sleeves required and therefore the number of installation components, whilst still retaining most of the strength of a sleeved single span system.

As the name suggests, Eaves Beams are used in conjunction with side rails and purlins to allow a fixing point for sheeting and gutters.

We manufacture a range of pre-engineered pressed structural channels to complement our cladding, Z-purlin and C-section ranges. Manufactured from high tensile Z39 steel in lengths of up to 6.5m. Pre-galvanised so no additional finish is required, our Eaves Beams satisfy the requirements of BS5950: Part 5 (1998). They are compatible with and ideally suited to a wide range of roof and wall systems.

This solution incorporates a full range of cleats, struts and brackets, facilitating a wide range of cladding system requirements.

- Versatile Design – accommodating varying roof pitches, can also be used in internal / external gutter arrangements. The Eaves Beam is purpose designed for use as an eaves purlin, top sheeting rail and a gutter support.

- Pre-Galvanised – no additional finishing or painting required.

- Pre-punched holes -minimising assembly time and errors.

- Wide range of sections and spans to suit an array of applications.

Dimensions

The diagram below refers to all Eaves Beams sizes (E-170, E-200 and E-240). The dimensions for a specific Eaves Beam can be referenced in the table below. Any stated dimensions on the diagram are relevant to all sizes.